Products

/

MELTING

MELTING

Melt-on-demand - only melting as much as necessary - is a key feature in all balti systems. Our aim is to transport the adhesive as gently and directly as possible to its destination. The system as a service to apply the hotmelt in the best possible quality.

Innovative melting technology for all reactive and non-reactive, low and high viscosity adhesives and sealants. High quality and economical like no other system!

MELTING

Melt-on-demand - only melting as much as necessary - is a key feature in all balti systems. Our aim is to transport the adhesive as gently and directly as possible to its destination. The system as a service to apply the hotmelt in the best possible quality.

Innovative melting technology for all reactive and non-reactive, low and high viscosity adhesives and sealants. High quality and economical like no other system!

Bag Melter

The balti bag melters were developed especially for reactive adhesives. Thanks to absolute tightness from the melting plate to the outlet at the application head, the sensitive adhesive is protected from external influences such as moisture. The great advantage of being able to work without inert gas (e.g. nitrogen) significantly reduces operating costs. A hydraulic cylinder presses the still cold adhesive against the melting plate, where it is melted at the lowest possible temperature and conveyed in the hose to the application unit.

With the unique PUME concept, balti has had a system on the market for years that is absolutely gentle on the adhesive. Whether smallest quantities or highly viscous polyurethanes, the continuously developed PUME technology can be used almost unlimitedly.

PUME-04R | for bag size 2kg with OD=130mm

PUME-28-H | for bag size 20l with OD=280mm

Special versions

- PUME-04/-05-Pre with pneumatic cylinder. Compact design.

- PUME-04/-05-S with enlarged chassis and control cabinet for additional electronics for additional functions such as accumulator, piston dosing unit etc.

- PUME-04-D / PUME-04-TDX / PUME-28-TZX / PUME-28-P4X for simultaneous processing of two different adhesives

- PUME-28-HIX without own PLC for a low priced integration into a complete system

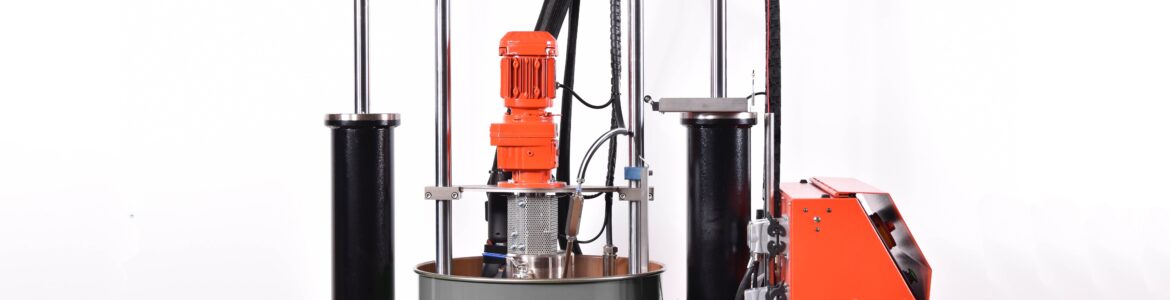

Drum Melter

The ideal device for applications with high demand for adhesives and sealants. A melting plate, perfectly tailored to the properties of the various melting materials and the desired melting performance, is pressed onto the adhesive in the barrel. Thanks to programmable heating power and adjustable cylinder pressure, adhesive is melted as required and pressed into the concentrically arranged pump inlet integrated into the melting plate. Depending on the type of adhesive, the appropriate pump conveys the melt material through one or more heating hoses to the application units.

- REA-20-Z for 20l hobbock and reactive hotmelt

- HSP-20-K / HSP-20-S for standard hotmelt and high viscosity sealants in 20l hobbock

- HSP-200-Z / HSP-200-K / HSP-200-S / HSP-200-M for various adhesives and sealants in 200l steel or cardboard drums

Variants:

- flat or differently structured and optimized melting plates

- Gear, piston, worm or diaphragm pumps for standard applications such as highly abrasive hotmelt

- manual to fully automatic drum change

- more or less melting plate pressure up to 6 bar pressure at the melting material

- Drum support and sheathing

- Pressure or speed control and much more...

Tank Melter

The balti tank melters are built to the highest quality level and come in many variants for practically every application thanks to their modular design.

For melting and conveying of meltable, non-reactive, self-flowing adhesives (thermoplastics) Hotmelt in granulate, "cushion", block or other form is filled into the top of the adhesive tank. A melting plate, which is optimally designed for melting, melts the hotmelt, which is then conveyed to the application head by a gear or piston pump through a heating hose. Size of the tank, design of the melting area, type and number of pumps, level sensors, control system and other advantages make balti systems stand out from the competition.

- TSG-4.5-K or-Z with 4.5l tank capacity(K=piston pump; Z=gear pump)

- TSG-19-K or-Z with 15l tank capacity

- TSG-29-K or-Z with 30l tank capacity

- TSG-90-Z with 90l tank capacity

Special versions:

- TSG-19 with extended control in a larger switch cabinet

- TSG-29 with pre-melting plate and two gear pumps for higher melting and delivery rate

- TSG-29 with pre-melting plate, reservoir, highest conveying capacity in the most compact design possible due to limited space in a mobile overall plant.

Dual Melter

Dual systems are used for the processing of two identical or different adhesives with sometimes different containers. E.g. two different reactive hotmelt or one of them non-reactive etc. The big advantage, in contrast to tandem systems, which are mostly used for the uninterrupted production of large quantities of the same material in drums and bags, is the compact design and thus low space requirement and a shared PLC control.

Cartridge Melter

Cartridge or adhesive without cartridge is placed in the container provided and heated. The adhesive melted at the outlet of the cartridge is pressurized pneumatically and conveyed to the adhesive valve or nozzle.

Hand-held cartridge device: the finger trigger switch controls the compressed air and the adhesive can be applied manually accordingly.

Cartridge device for stationary or automatic application: with the foot switch or external signal the valve is opened and the adhesive is applied.

balti can offer innumerable expansion options for the cartridge devices, such as: special nozzles as well as small slot nozzles, application control, adhesive management for reactive adhesives, dosing pumps, etc.

- HAG-200 (without cartridge)

- HKG-300

- KSG-300 (with or without cartridge; with pneumatically controlled valve and expansion options)

Cartridge sizes: 310ml, ø47mm