Hotmelt Melting Techniques

Hotmelt system technology refers to the technology and equipment required for processing hotmelt plastics.balti offers the optimum melting technology for every adhesive and sealant, whether melting granules, blocks, and sheets in a tank or melting from a specific container. Container-specific melting technologies such as bag, drum, and cartridge melting technology use a particularly gentle melting process.In these cases, only as much adhesive or sealant is melted as is needed for the application. The larger the surface area on which the adhesive melts, the more energy can be transferred. Since the adhesive, as a plastic, has a rather insulating effect, the heat does not really want to penetrate the adhesive. The amount of heat required varies depending on the type of adhesive and is not linear across the entire temperature range. The melting performance can be greatly influenced by applying greater pressure to the material to be melted and allowing it to flow out of the pump outlet at a correspondingly faster rate.Depending on the required melt quantity, balti provides the appropriate system size with a correspondingly designed melting plate, always following the motto: only melt and thermally load as much as necessary. Furthermore, the following applies: as perfect as possible in terms of flow, “first melted – first applied.”

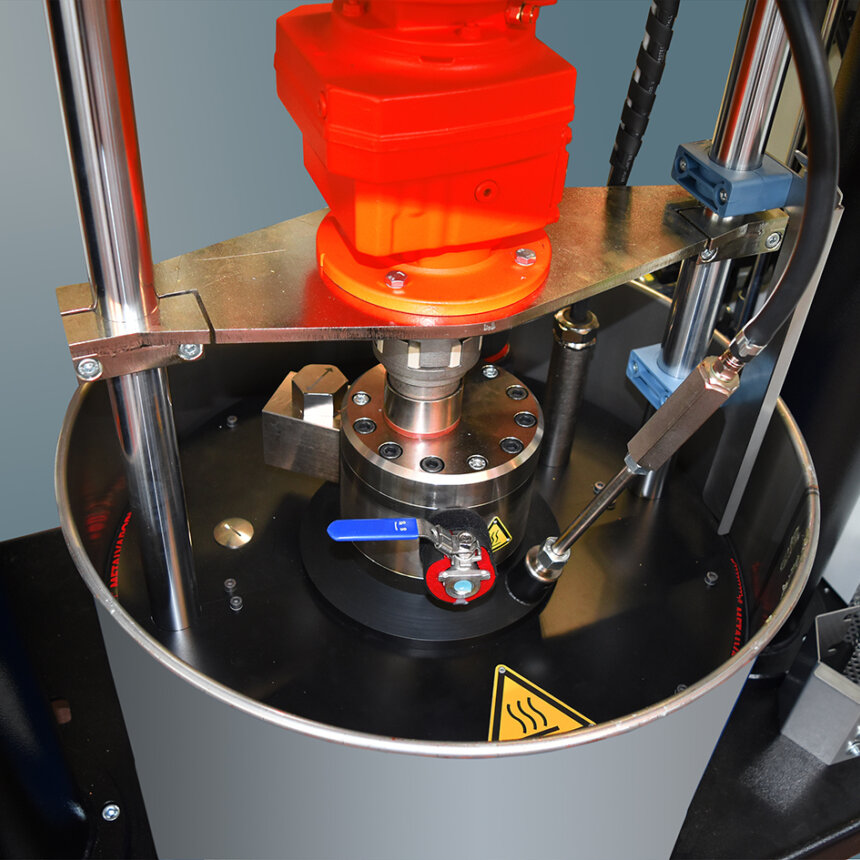

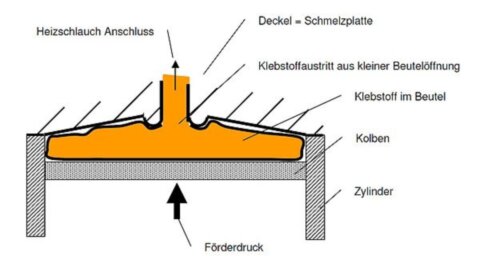

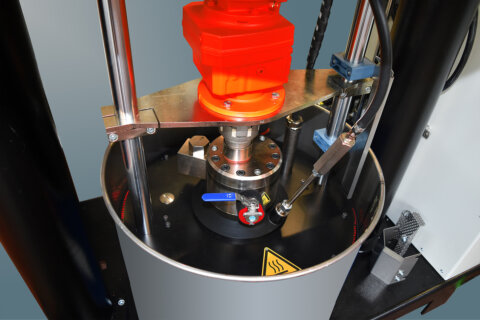

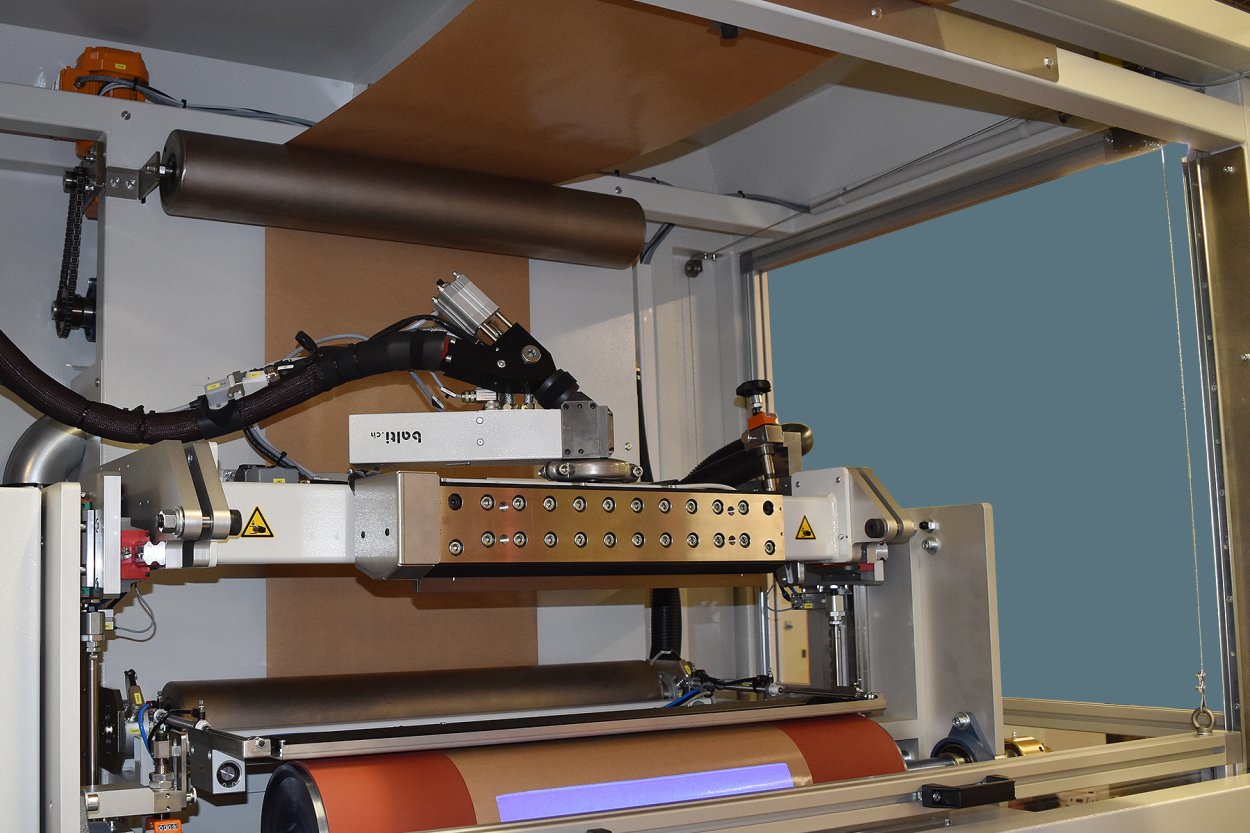

- Bag Melting Technology PUME-principle

- Drum Melting Technology

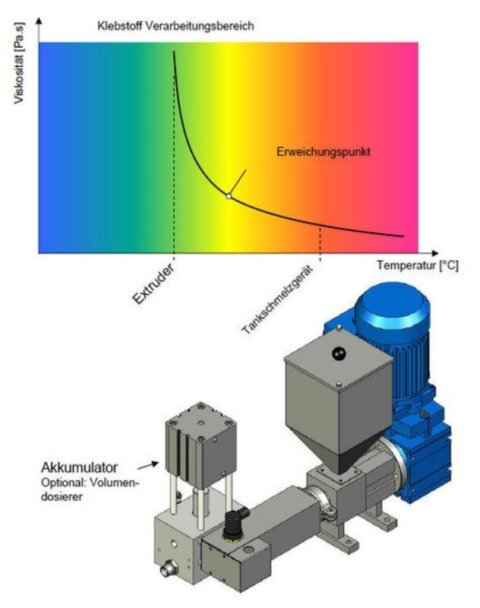

- Tank Melting Technology

- Extruder Technology

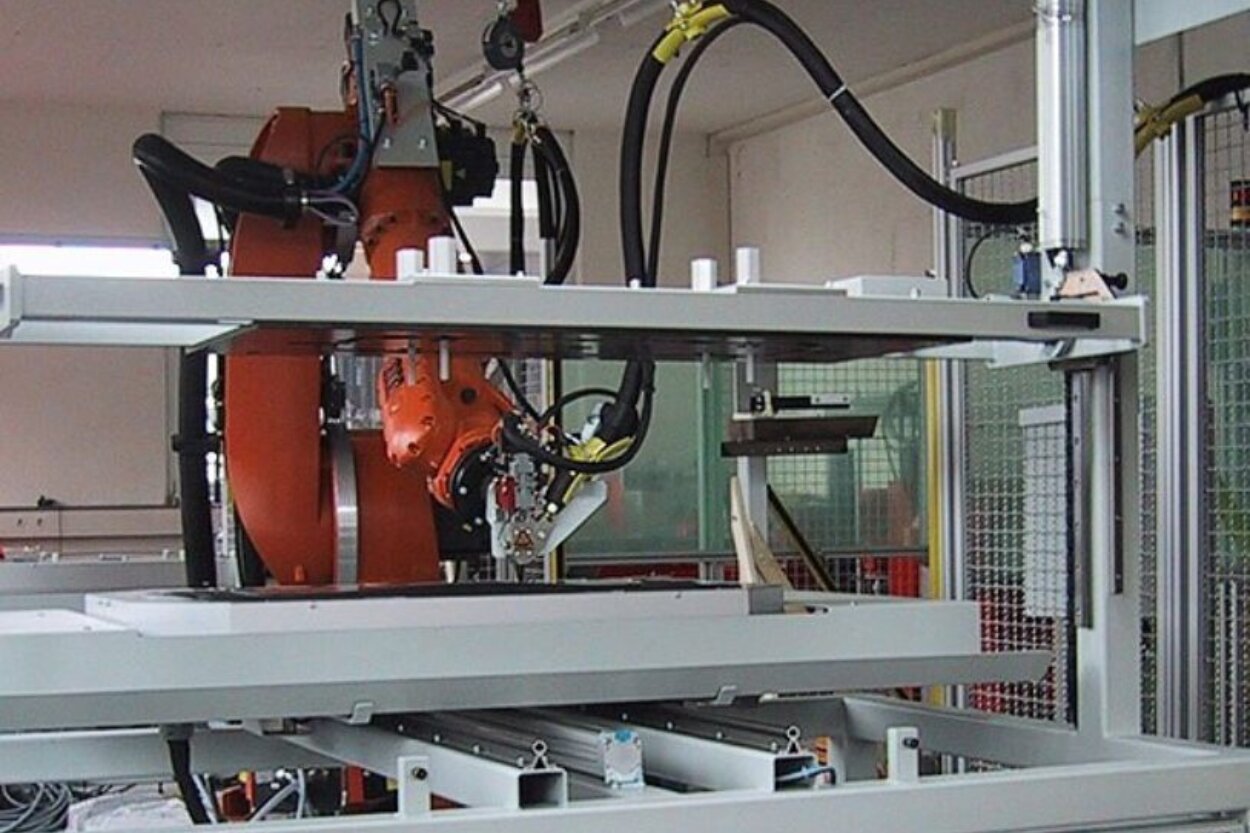

- Customized or Application-Specific Hotmelt System