Hotmelt Procedures and Applications

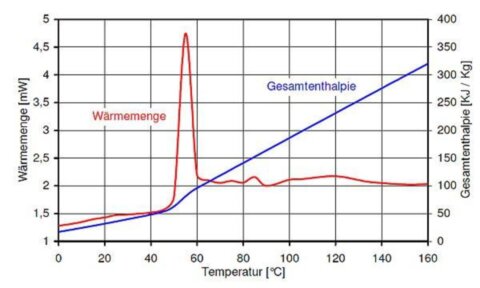

Hotmelt is a process in which thermoplastics are heated to a liquid state so that they can then be shaped or bonded. Hotmelt adhesives and sealants are supplied in a wide variety of forms and packaging, depending on the type and application quantity. balti systems melt, convey, dose, and apply the material as a loose product or directly from the packaging. Once liquid, it is applied to the desired location using pressure, usually supported by a pump, via a hose, possibly with an intermediate storage tank, using an application head/nozzle. Once applied, hotmelt must be joined, laminated, and laminated as soon as possible or after a subsequent remelting process, usually under the influence of force/pressure. As a system supplier, balti offers application systems and complete systems.

- Melting

- Conveying

- Reservoir

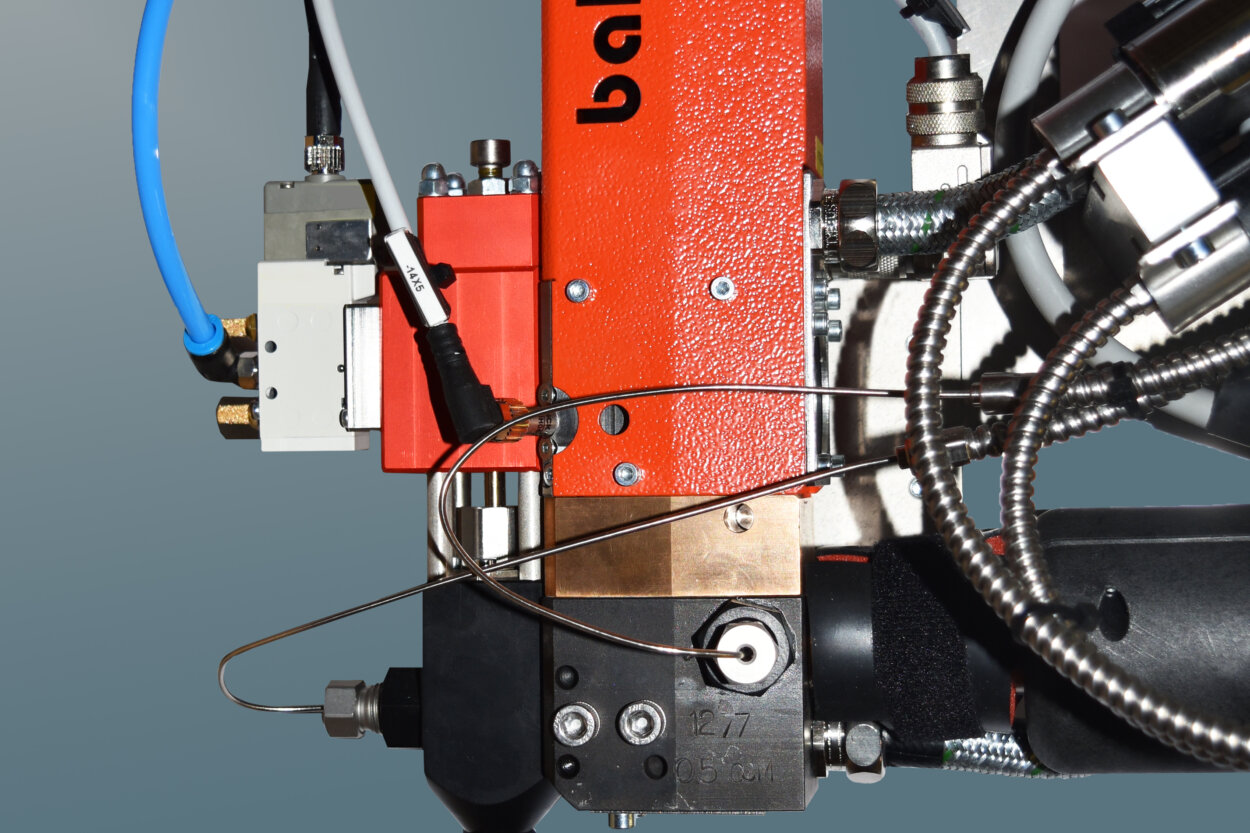

- Dosing

- Application in general

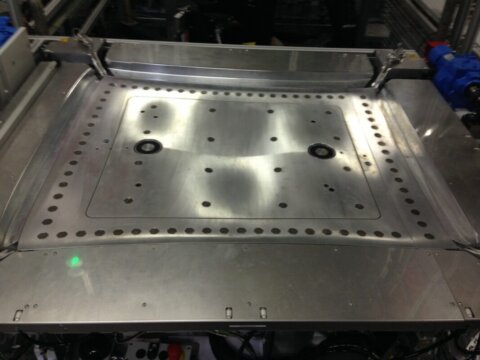

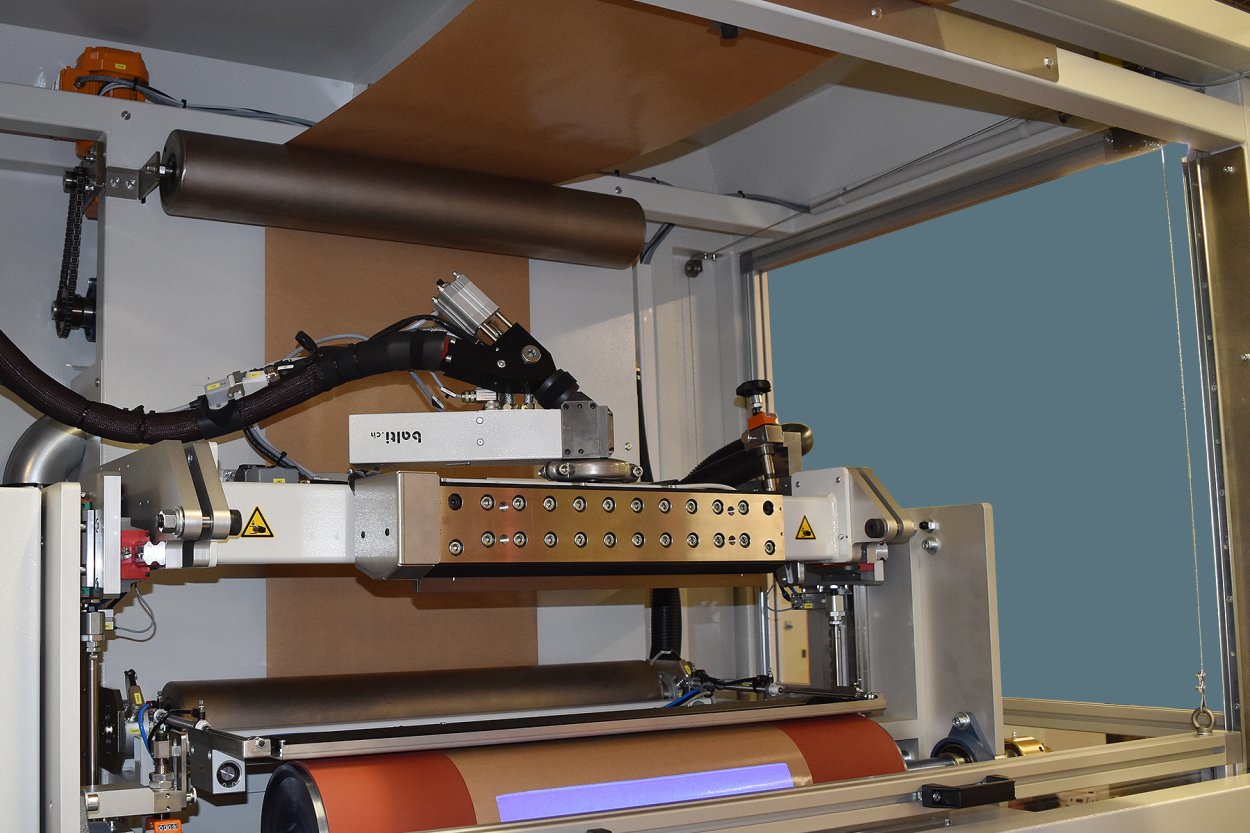

- Coating

- Joining / Pressing

- Laminating

- Edgefolding

- Overmoulding / Injecting

- Mixing / Colouring / Foaming