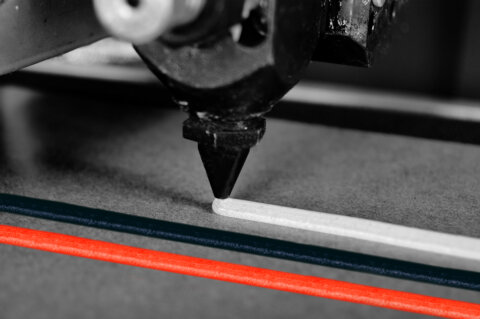

For full-surface application of hotmelt adhesive onto flat, rigid, or soft and flexible workpieces (cut parts), roller coating is virtually unmatched. Using the roller, the adhesive can be applied onto the substrate or even pressed into the fabric. Roller systems are also used for mesh-like materials or when partial coating is required. A finely metered adhesive film on the roller is transferred to the substrate in a process comparable to offset printing.

Adhesive application is achieved through direct contact between the substrate and the application roller. A wide range of parameters determines the adhesive laydown and is defined during commissioning. Programmable and automatic changeover is recommended when processing many different materials frequently.

- Adhesive application width from 10 to 2,500 mm; up to 1,050 mm using the closed-tank principle; beyond that, open double-roller principle

- Adhesive coat weight: 10–300 g/m²

- Production speeds up to 40 m/min

- Countless options for processing different materials, automation upgrades, handling solutions, premelters, etc.

- Best-in-class for reactive hotmelt adhesives

Standard roller coater sizes:

- WAG-150

- WAG-300

- WAG-450

- WAG-650

- WAG-820

- WAG-1050

Example: WAG-150 corresponds to an application width of 150 mm. Smaller or larger application widths than the listed standard sizes are available on request.