Mixing, Coloration, Foaming

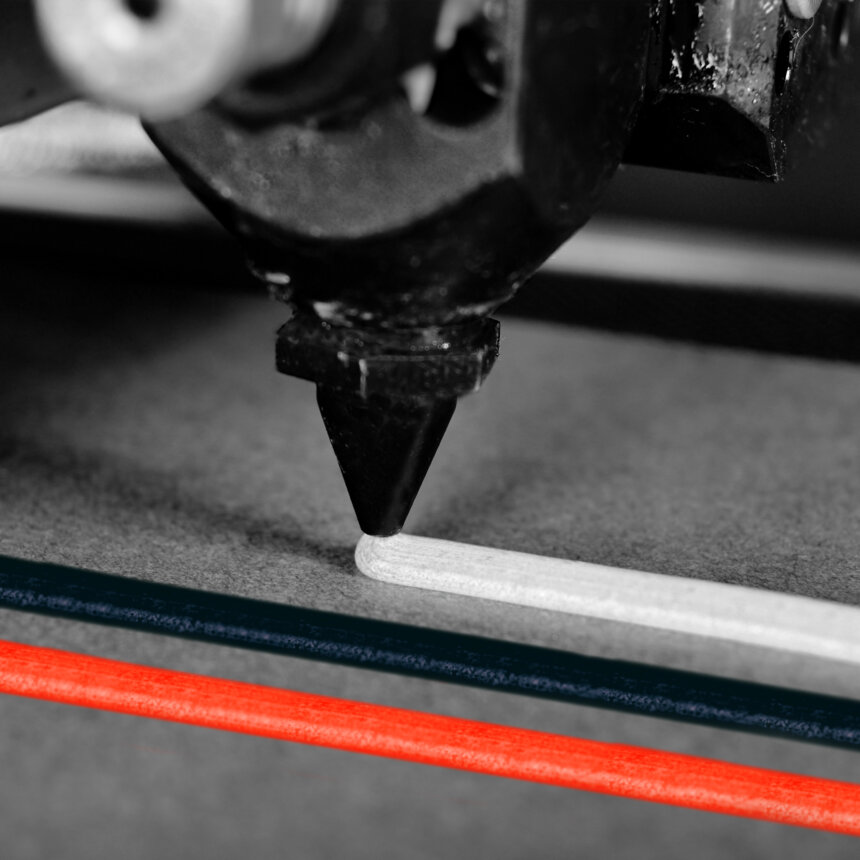

Most typical hotmelt adhesives are single-component adhesives. This is also a significant advantage of hotmelt adhesives over two-component adhesives and sealants. Reactive adhesives obtain the second component from the air (moisture) after application. However, there are special applications in which two media must be mixed while hot. balti also has unique solutions for this and, with its proven metering pumps, can supply a 2-component or multi-component hot melt mixing system (HMM) with almost unlimited possibilities. There is high demand for coloring hotmelt immediately before application. This eliminates special costs for the procurement and management of hotmelt in specific colors. The system can also be converted immediately without having to clean the entire equipment. In what is probably still a unique development, balti has developed a cost-effective system (color mixer – FM) that can also be retrofitted.