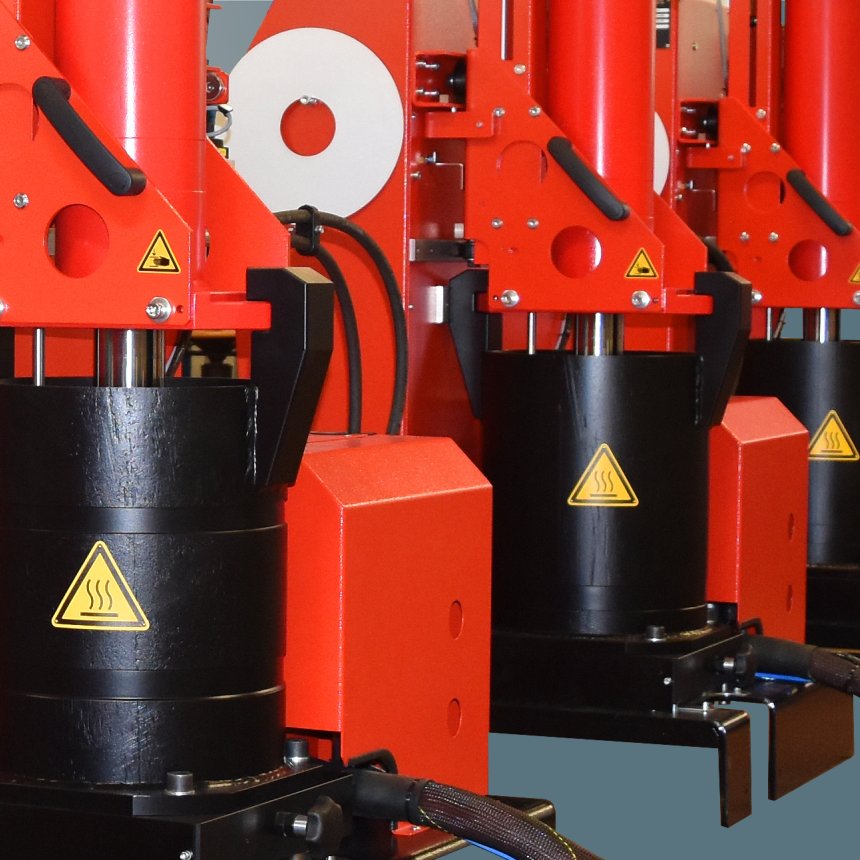

Melting Equipment

Melt-on-demand – only melting as much as necessary – is a key feature in all balti systems. Our aim is to transport the adhesive as gently and directly as possible to its destination. The system as a service to apply the hotmelt in the best possible quality.Innovative melting technology for all reactive and non-reactive, low and high viscosity adhesives and sealants. High quality and economical like no other system!