Various and very innovative standard and self-developed sensors can be a low-cost, but also high-quality solution.

Compact vision systems, as increasingly marketed by a wide variety of suppliers, still satisfy application requirements in only a few cases. High-end vision systems can solve practically any problem. balti is glad to help with the evaluation and implementation in a complete system.

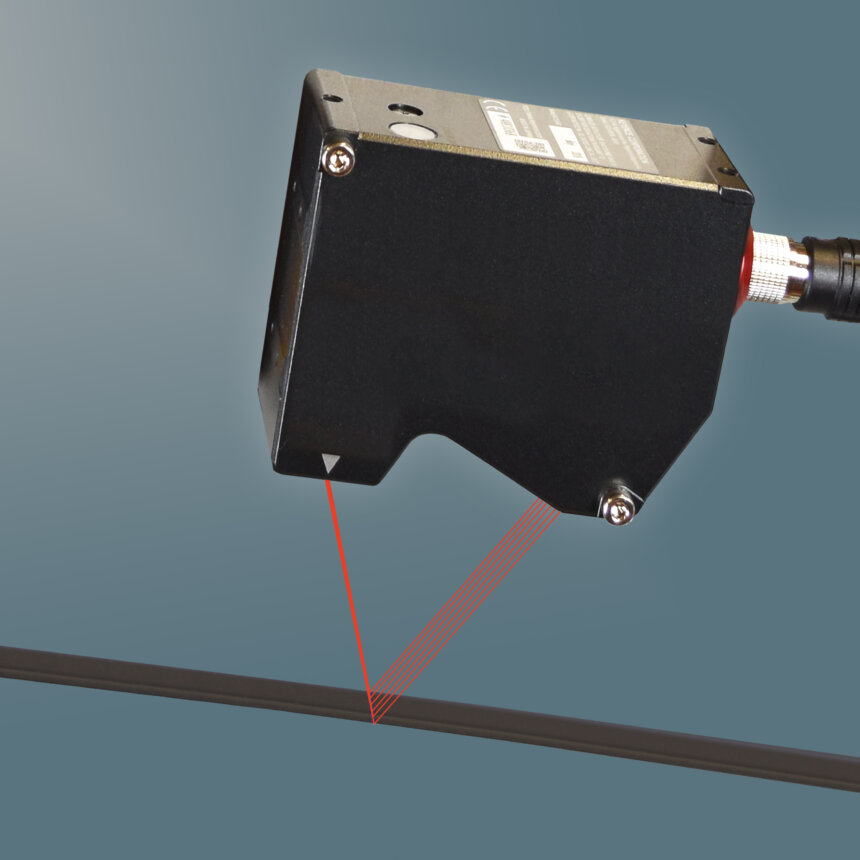

Point or laser cut sensors, "trailing" the application or in a second process step, including their evaluation and presentation on a display, enable the presence and quantity of the applied bead to be checked. balti also offers complete systems with component tolerance compensation.